Silo, Bunker and Damper Lining

BUNKER VE SILO LINING

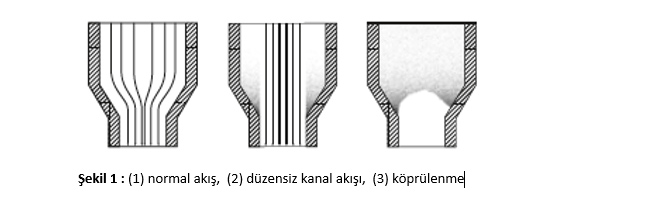

For bulk goods such as coal, salt, gravel, gypsum etc., bunkers and silos are the simplest and most economical type of storage. Two important problems that might occur during material transfer is caking and bridging. Normally, the bulk material is discharged across entire bunker cross-section (1). Due to narrowing of the cross-section and increasing friction ratio, the mass flow shifts to a funnel flow (2). The additional incoming material compacts and forms a dome, which is positioned on the inclined planes of the bunker (3)

Removing the material bridge is time-consuming and there is also a danger of dust explosions. Lining the bunker and silo with SIMONA PE 500 and SIMONA PE 1000 helps to avoid disruptions. Fluids can flow easily on the bunker surface without residues. By this way, removing bulk materials form bunker with lower inclination angle is possible.

Usually sheets from 8 to 20 mm thick in standard dimentions 1000x2000 mm or 1250x3000 mm are preferred although SIMONA has wider product range.